FLUX MAX WITH POWERBOLT II

The Flux Max was engineered as a fully modular tattoo machine, offering unmatched flexibility and customization. Its design allows artists to swap components easily, including the machine’s body and grips, without needing to invest in multiple devices. Because the stroke is determined by the machine’s body, changing the body lets artists quickly adapt to different tattooing styles. The Flux Max is also backward-compatible, meaning it seamlessly interfaces with previous FK Irons grips and PowerBolt wireless battery packs. This ensures that artists can upgrade to the latest technology without replacing their existing equipment. We wanted to release a flagship machine that paired perfectly with the Powerbolt II and all the innovations it offers. This is the first machine with state-of-the-art technology that learns how you like to work, from the type of ink to the tip/needle, the level of pressure you apply and setting choices. It senses, adapts and optimizes for a smoother tattooing experience.

The main goal was to develop a new design language for the FLUX line of tattoo machines and fully transition the line to a modular system. We wanted a dynamic form with sweeping chamfers that matched the Powerbolt II and an overall refresh of the silhouette. We also spent time updating and refining the inner mechanism to make sure the machine consistently packed into the skin. By doing so, we created a new 4.5mm stroke offering that was mostly aimed at lining and packing large areas with color. The development of the Powerbolt II was the biggest undertaking the team did thus far. We wanted to keep the a similar silhouette while incorporating the new visual direction. It was also going to launch with the new Flux MAX, so we need to ensure a seamless design throughout. Making it part of the new Modular Collection was crucial for the development moving forward. It needed to fit within the newly established ecosystem of tattoo machines and accessories. The board and LCD screen were already sourced so the challenge came from trying to create a cohesive experience that made it easy for our artists to use. The decision to stick with a membrane came from not only shorter lead times, but it actually allowed the device to stay "water-resistant" and make it easier to wipe clean after every use. The product is currently in production and is for sale on FK Irons' website here.

Role: Industrial Design , Design for Manufacturing , UI/UX Interface & Product Visualization

Engineering Team: Christian Bonomo , Fernando Diaz

A New Generation of Tattooing Machines

How do we innovate on a flagship product? This was the driving question that guided the development of the Flux Max. The goal was to give more control and better reliability to the tattoo artists. By pairing it with the Powerbolt II, the machine’s power and features can be adjusted directly on the device. The newly added 4.5mm stroke was introduced for those artists that create fine line tattoos and need a machine that can really pack color into the skin. The updated design language signified a new, and dynamic machine that fit FK Iron’s vision on the future of the tattoo industry. It conveyed a sense of strength, speed, and futuristic appeal while creating an iconic silhouette.

Redesigning the Iconic Silhouette

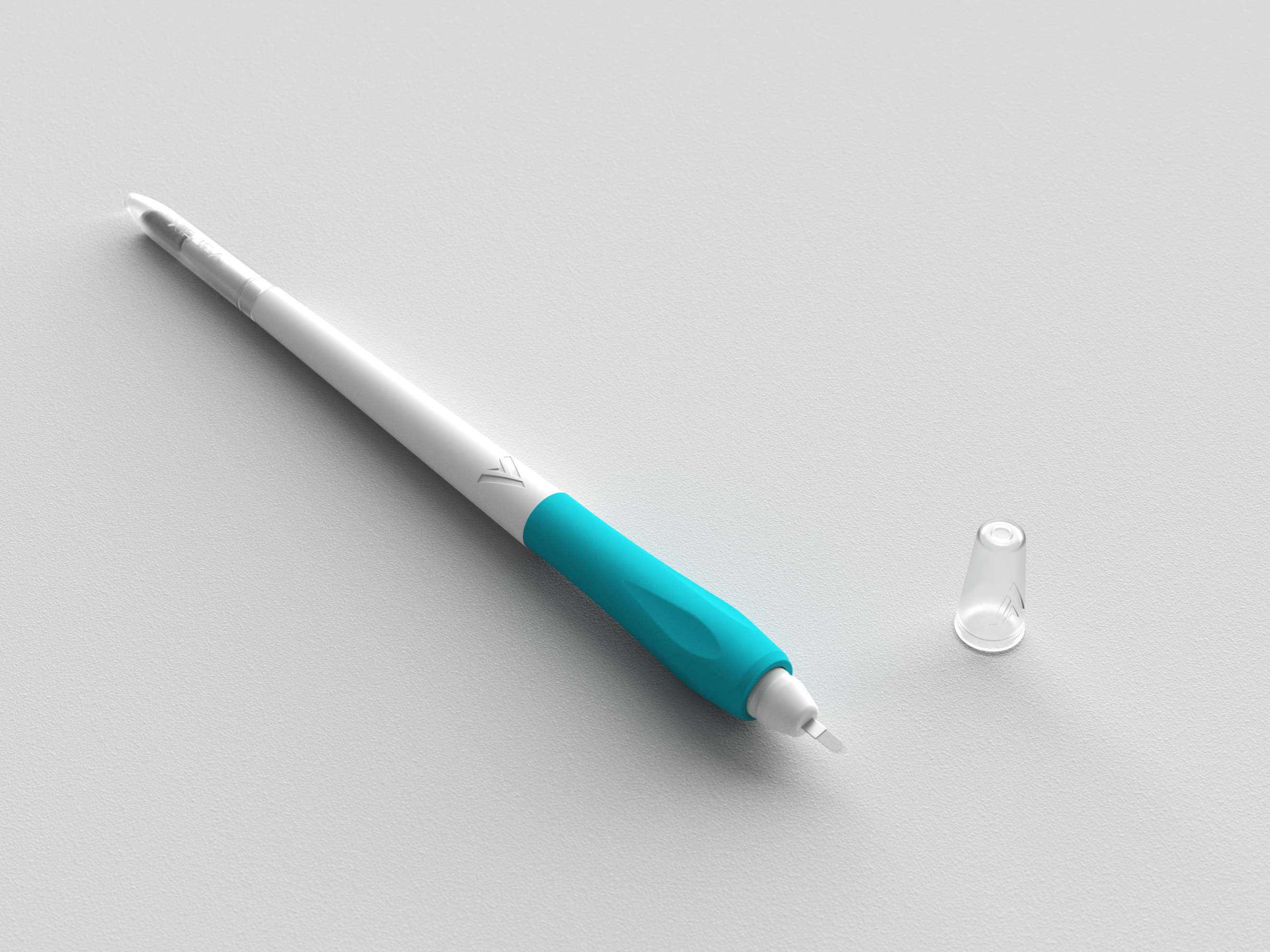

Updating the design language was crucial for the launch of the Powerbolt II and the Flux MAX. We wanted to represent a more refined, yet edgier direction. The goal was to have light reflect off the edges and captivate artists with a new silhouette. The sharp, angular lines give the machine a sense of precision and strength, conveying a confident identity to our artists. The sweeping chamfers, which transition smoothly between surfaces, add a dynamic and refined touch, emphasizing the machine's sleek and contemporary appearance. This reflected our mission by committing to always finding new and innovative features to bring to our dedicated artists.

The design revolved around the main motor housing. This was the key component that the grips and battery pacts interacted with. The milled aluminum housing with a tightly packed motor mount delivers unrivaled performance. The newly added 4.5mm stroke meant that the machine’s tolerances needed to be tightened so that the overall construction did not loosen when the machine was operating. The threading was even extended to accommodate a longer “needle throw” (when an artist adjusts the length in which the needle sticks out from the machine) so that artists could dial in their preferences even further.

Powerbolt II Development

The Powerbolt II marked a significant move forward for FK Irons because it was going to be paired with the new Flux MAX. Since it was going to be paired with a new tattoo machine, we took the opportunity to design the 2 with the new visual direction. We wanted to convey a sense of strength, speed, and futuristic appeal while creating an iconic silhouette. By adding chamfers into the design, we created smooth transitions between surfaces and emphasized precision. Throughout this process, collaboration with cross-functional teams, including engineers, marketers, and product managers, was essential to ensure the successful development and launch of the next iteration.

New Features & Updated Interface

Building upon the success of its predecessor, the PowerBolt II not only maintained FK Irons' reputation for exceptional quality and craftsmanship but also introduced groundbreaking features tailored to the evolving needs of tattoo artists worldwide. With its enhanced precision, and ergonomic design, the PowerBolt II empowered artists to push their creative boundaries while ensuring consistent, reliable results.

Once the LCD screen was sourced, the challenge came from finding the right way for the artist to interact with the device. We wanted to keep the membrane inputs because not only was it featured on the original Powerbolt, but it provided a great water-resistant option that was great for easy cleaning. The new digital readout clearly showcases the new features and can be customized to their preference. We added a timer to help keep track of sessions and added a "Power Display Mode" that switched between Hertz and Volts (allowing artist to fine tune their machine). It also features a more responsive eGive feature that helps absorb some of the impact from the needles on the skin to alleviate pain to the client. Ultimately more menus were added to improve the options available to artists like the orientation of the screen.

Cultural Impact: The New Standard

The launch of the Powerbolt II along with the new Flux MAX not only solidified FK Irons' position as a leader in the industry but also underscored their commitment to driving progress and excellence in tattooing equipment. It has become the main go-to machine more many experienced artists around the globe and has brought more artists to the brand. They trust our promise to always deliver a meaningful experience to them and provide them with the best tools for the job.